Machine building: From ideas to solutions

Our experienced team ensures that your mechanical engineering projects are completed precisely according to specifications, while also ensuring ergonomics, safety, and reliability.

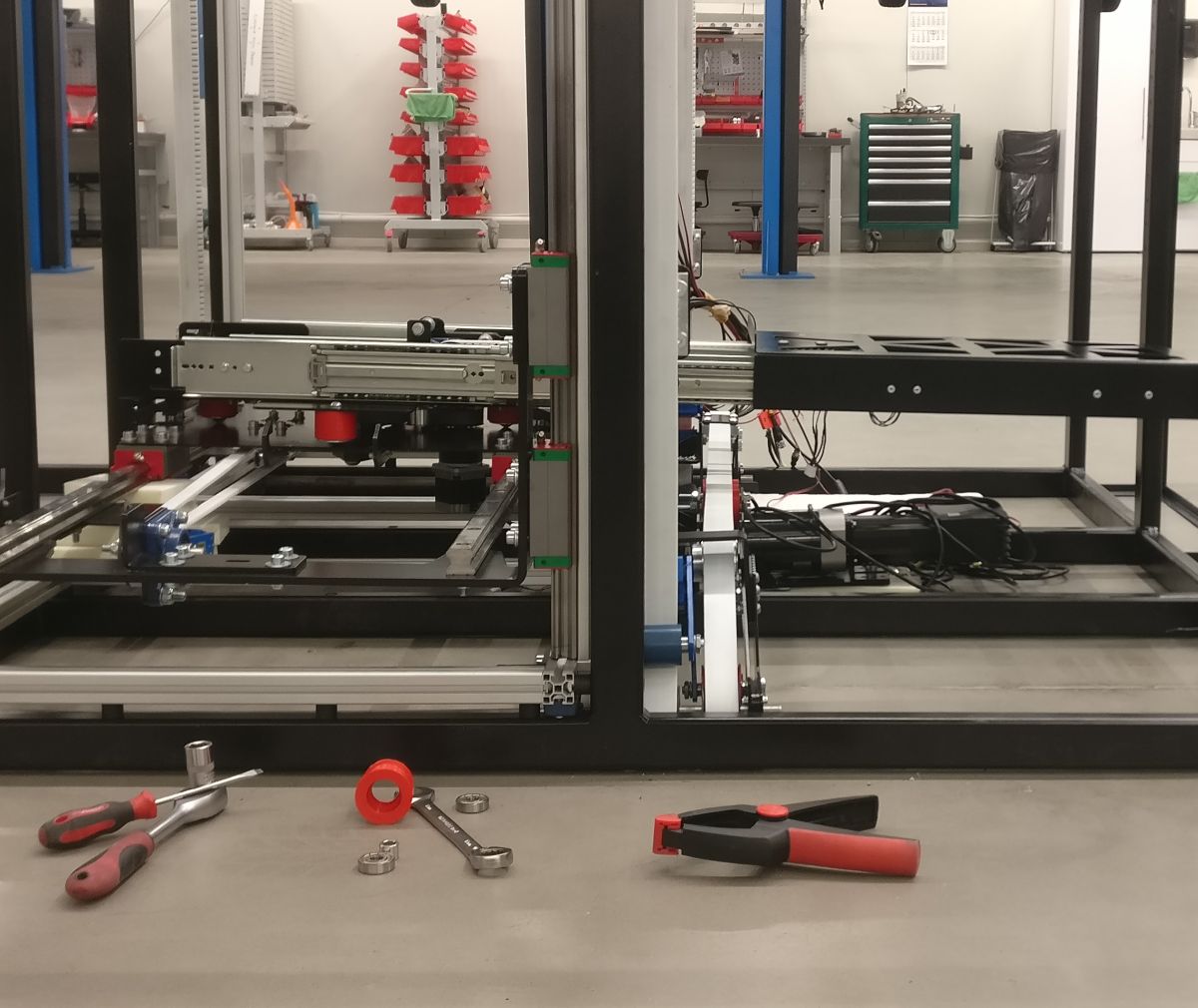

Automated systems

Insero OÜ's main activity is providing mechanical engineering design services. We carry out engineering and technical solutions and design for various machines and equipment.

According to the client's needs and wishes, we develop a concept for which we then create the project, models, and drawings.

Upon completion of the project, we hand over the equipment to the client, along with the necessary documentation and training, and offer subsequent aftercare.

We design the following equipment and systems:

– Process equipment and their components

– Conveyors and transport systems

– Production equipment and lines

– Assembly equipment

– Labeling and marking equipment

– Sorting systems

– Feed systems

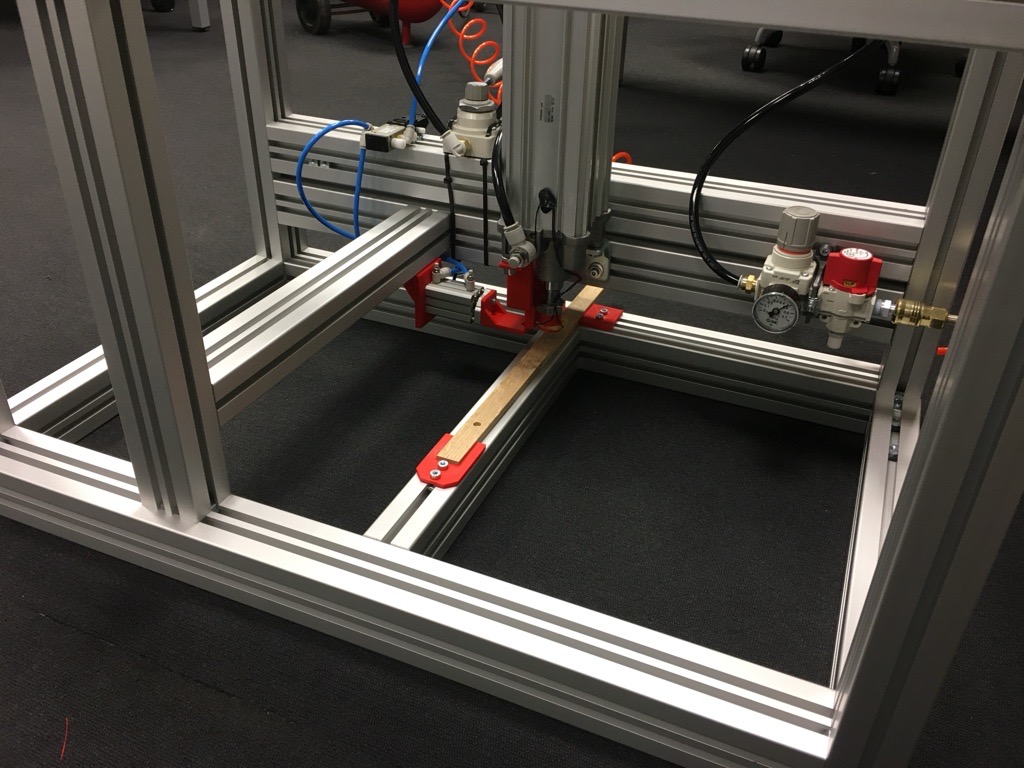

Jigs

The speed or efficiency of any production work is the starting point for calculating added value. Regardless of whether the process is manual, semi-automatic, or fully automatic, optimal working positions, precise positioning, and repeatability are key for achieving greater profitability. In designing fixtures, we place significant emphasis on efficiency as well as on ergonomics and maintainability. We have created solutions for various industrial sectors, including metal, electronics, medical, wood, and others.

- Jigs for manufacturing

- Stationary jigs

- Assembly jigs

- Special tooling

Montage planning

A significant cost component in investing in production is the time spent on the assembly of equipment and its associated infrastructure. This has two components - the direct cost of the assembly team and the additional cost associated with halting regular production. At Insero, we place significant emphasis on designing our equipment and structures to be quickly installed and configured, significantly reducing downtime. For this, we use 3D laser scanning to map the existing environment. We offer process planning for both assembly and prior disassembly.

-Logistics planning on-site (including indoors)

-Preparation of assembly plans

-Creation of assembly videos

-Preparation of physical scale models

-Consultations

Other services

Product Development and Prototyping

We are involved in both the development of new products and the improvement of existing products according to client and market expectations.

3D-scanning

Through laser scanning or 3D surveying, it is possible to create an accurate spatial point cloud of the environment or objects. The results can be used for mapping and analyzing existing buildings and equipment in various fields.

Consultations

According to the client's needs, we can assist with additional static and dynamic analyses (FEM), project management, and technical consulting.

Software Development

The service is aimed at optimizing mechanical engineering workflows by utilizing the capabilities of Autodesk Inventor API, iLogic, and Vault server.